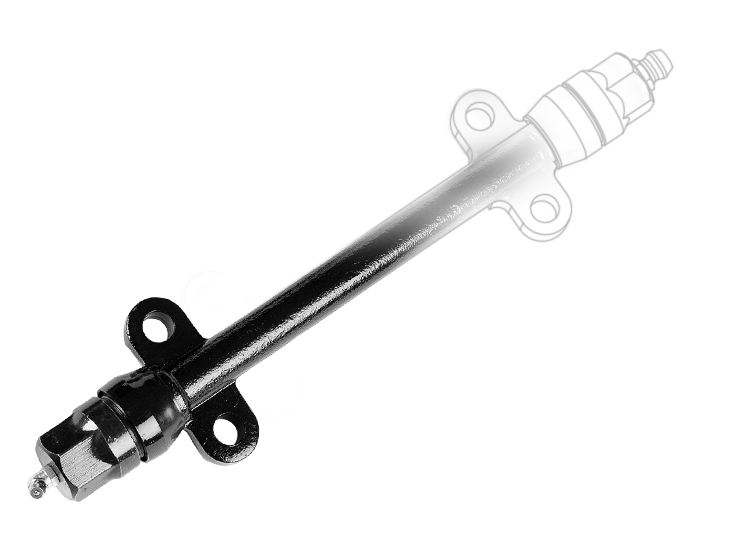

Installed on independent double wishbone suspension system

Inner arm shaft kit is installed on independent double wishbone suspension system. Its function is to secure control arm on to chassis. Inner arm shaft kit has upper inner shaft and lower inner shaft. The shaft with bolt hole is secured on to chassis, and thread bushing is connected to control arm. At the same time, it is also tire positioning parts. Inner arm shaft kit will be secured between control arm and chassis, so that angle can be adjusted when turning.

Customized Service

We understand your needs, so we provide customized services to create the ideal product that fits your mind.

- 3D design, Accurate and Correct

- Excellent material, Cast Molding

- CNC machining, Precise Efficiency

- Custom Color, Professional Processing

- Surface Treatment, Various Solutions

- Multiple Security, Brand Positioning

- Trust Measurement, Quality Assurance

- Complete Packaging, Efficient Shipping

Features

Inner arm shaft kit is made up by integrated forged steel. After perfect processed by CNC lathe machine, the accurate thread and grease nipple lubrication design can ensure components turn smoothly and stably.

Size fits with genuine standard, and is easy to install

Integrated advanced forged steel, ensuring metals parts are strong and durable

Body metal strength fits with genuine standard, strong material has good capacity.

Surface is treated with antioxidant to lengthen use life

Manufacturing process

We considers that the products are suitable for all kinds of harsh weather conditions and road conditions. Through global service feedback, we collect environmental data of local roads. R&D products are strictly measured and calculated, and materials are strictly checked, and the manufacturing process is constantly pursuing better construction methods. Provide reliable products.

Production process

From the mold design, processing, stamping, forging, cutting, drilling, welding, quality control, product assembly to finished product packaging, each process affects the quality of the product, and the company strives to improve its quality and efficiency by standardizing the production process. At the same time to meet the needs of customers.

Complete product model

Up to more than 7,000 kinds of product parts data database to meet the needs of different brand models and vintage parts.