Manufacturing

Product life depends on its manufacturing process

Superior quality and consistent product is basic goal of UIL FU’s production management. Providing safety first product is UIL FU’s perseverance. UIL FU will use all kinds of harsh weather and road conditions for testing. Quality and safety are trustworthy.

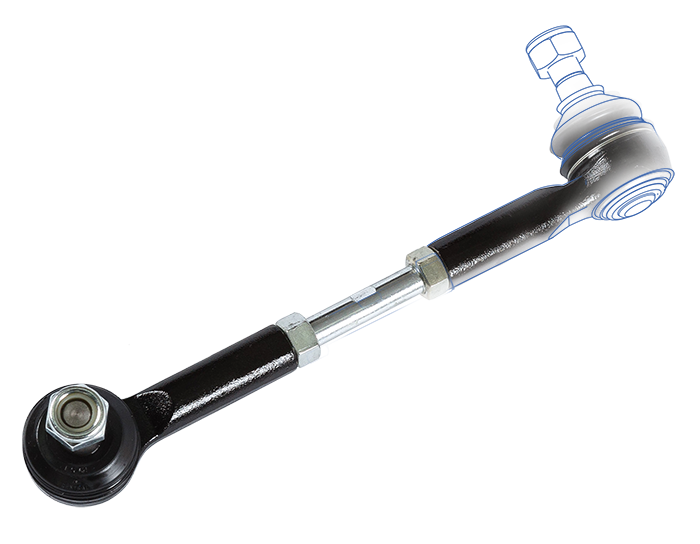

Innovative R&D, precise appearance design

Using genuine product as design standard, under constant innovation and improvement, we use 3D new technology to assist design and to control development of new products. We achieve efficiency and aesthetic demand through automatic welding.

Ball stud, bushings, sleeves and other product

accessories are assembled correctly to

ensure that the product function is normal.

The drilling of the products are all measured and designed

according to the original standards, so as to

ensure accuracy.

In the allowable range of mechanical

automation, automatic welding is used to

make the finished product exquisite.

Excellent material selection

We choose qualified steel raw material and reasonably design product manufacturing process to accurately temper, refine, and produce tough and strength qualified products. Axis and ball joint uses high-toughness alloy structural steel. Adding chromium and molybdenum elements, component is stable, purity is high, decarburization layer is small, cold cracking rate is low, heat treatment quality is stable, hardness is equal, and quenching is good. At the same time, we choose suitable dust cover to effectively lengthen durability life.

-

Good Quality

Carbon Steel -

Axis

HRC27~33゚ - Dust Cover

- Plastic Bearing

Consistent production process

From material selection, molding, stamping, cutting, electrical welding, assembling to packaging, we use consistent production process. With gradual introduction of automatic production machine and self-developed processing mold, it increases production efficiency, allowing quality and efficiency satisfy customer need.

Strengthen product corrosion resistance

Surface of steel part uses various anti-corrosion and anti-rust treatment, such as plating, electrophoretic deposition, Japan trivalent chromium, anodize, phosphate, black oxide, sand blasting and anti-rust, powder coating. At the same time, product quality is control by tests, like salt spray test, to effectively resist air oxidation and acid rain erosion.

Friction resistance

Precision cutting, drilling, and the use of high-strength materials, to ensure the low friction and toughness of the ball head, slow down the friction caused by external environmental forces caused by friction. At the same time, it is applied with high-quality lubricating grease, which is resistant to water, anti-aging and corrosion, and abrasion resistance, so that the product has a strong bearing capacity; and excellent adhesion and lubricity are also well compatible with rubber parts. And can have a stable operating temperature range, effectively extending product life.

Shock absorption and shock resistance

Using high strength lightweight aluminum alloy material, high strength steel raw material, temper, and accurate structure design and construction to strengthen the ability of product shock absorption and shock resistance.

Weather resistance to meet global market needs

Rubber, grease, and steel material used by UIL FU not only can resist weather (temperature and humidity), but also are heat proof and cold proof. After completing the products, they are tested for fatigue for durability in order to reach genuine standard.

Exceed quality performance of the same trade

Rigorous production process and quality management, complete the task of customer delivery, the product not only meets standards, but also exceeds expectations.

Tested by NIPPON STEEL & SUMIKIN TEVHNOLOGY Co., Ltd. with Uil Fu and Japanese original control arm.

Uil Fu : a maximum load of 42.54kN and a maximum load capacity of 26.8 mm,

Japanese : maximum load of 34.73 and the displacement of 8.37 mm.

More than 40 reliable tests

Product quality comes from safety belief conveyed by persistence of reliable tests. UIL FU provides 5 categories and over 40 quality control tests to ensure high standard of product quality.

- Cold and thermal shock

- Salt spray test

- Durability test

- Material strength test

- Dimensional inspection

- Ball stud detection

- High temperature strength

- Gap test

- Tempering

- Temperature work

- Pull-out test

- Material analysis