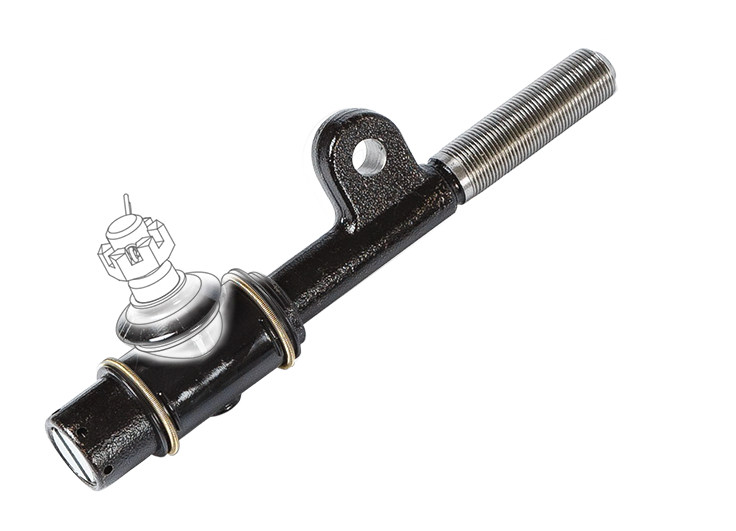

One of the car steering tie rod parts

Tie rod end is a part of auto steering. It connects to steering tie rod through spiral connection with rack end, providing better sense of control for drivers. Tie rod end is located near the wheels, and the position is called outer tie rod end. Rack end that is close to inside is called inner tie rod end. The main function of tie rod end is to push and pull tires, directly affecting stability of control, safety, and tire use life. When driving, tires will bump due to uneven road, but rack end is mainly fixed to car body, and tie rod end can exert its vertical and horizontal steering function.

Reminder: Worn tie rod end can cause drifting, unstable steering, and severe tire damage. After installing new tie rod end, wheel alignment must be done.

Customized Service

We understand your needs, so we provide customized services to create the ideal product that fits your mind.

- 3D design, Accurate and Correct

- Excellent material, Cast Molding

- CNC machining, Precise Efficiency

- Custom Color, Professional Processing

- Surface Treatment, Various Solutions

- Multiple Security, Brand Positioning

- Trust Measurement, Quality Assurance

- Complete Packaging, Efficient Shipping

Features

Tie Rod End is forged from high quality material. After heat treatment, it achieves better grain structure, ensuring wear resistance, and excellent durability. Through accurate design, tie rod end makes sure smooth driving and sensitive response of steering function.

Paired with UIL FU’s accurate ball joint structure design, it provides smooth steering experience.

Tie rod and ball joint are integrated, which has highest intensity and tenacity.

Surface enhanced processing like anti-oxidization and anti-rust, strong material has good capacity.

High intensity pull test to practically test the product is better than genuine.

Test with strict reliable tests to ensure superior quality.

Manufacturing process

We considers that the products are suitable for all kinds of harsh weather conditions and road conditions. Through global service feedback, we collect environmental data of local roads. R&D products are strictly measured and calculated, and materials are strictly checked, and the manufacturing process is constantly pursuing better construction methods. Provide reliable products.

Production process

From the mold design, processing, stamping, forging, cutting, drilling, welding, quality control, product assembly to finished product packaging, each process affects the quality of the product, and the company strives to improve its quality and efficiency by standardizing the production process. At the same time to meet the needs of customers.

Complete product model

Up to more than 7,000 kinds of product parts data database to meet the needs of different brand models and vintage parts.